Wide fin spacing availability reduces the affect of frost build up on low temperature applications. However this will increases the pressure drop in the refrigerant side and performances of the.

In both methods the cooling coil is treated as a single zoneregion and hence the required surface area is determined 2.

. Which are usually based on log mean enthalpy or log equivalent dry-bulb temperature difference. Fin style0Straight 1Slot 2Triangle wave 3Sine wave Tube material-1See notes 0Copper 1Steel 2Aluminum Fin material-1See notes 0Aluminum 1Copper 2Steel. Evaporator Coils Single dual or quad compressor circuits allow precise capacity control.

Coil arrangement 0In-line 1Cross. Air passing across the fins is cooled as the refrigerant flowing through the tubes absorbs heat and is boiled evaporated. Refrigerant flowing through the coil tubes is controlled by a thermostatic-expansion valve.

Splitting a DX Evaporator coil is one of the toughest concepts to understand in the coil business. Knowledge there is not an existing distributed simulation model for the study of tube circuitry of evaporator coils. Splitting the coil simply means that 2 compressors can operate off of the same coil.

By varying the combination of key design variables coil materials coil geometry casing design air units are very versatile heat exchangers with a great variety of. Evaporator Like the condensing unit evaporator coils also have performance curves Figure 2. For it to boil flash the liquid must absorb heat from its surrounding environment thus.

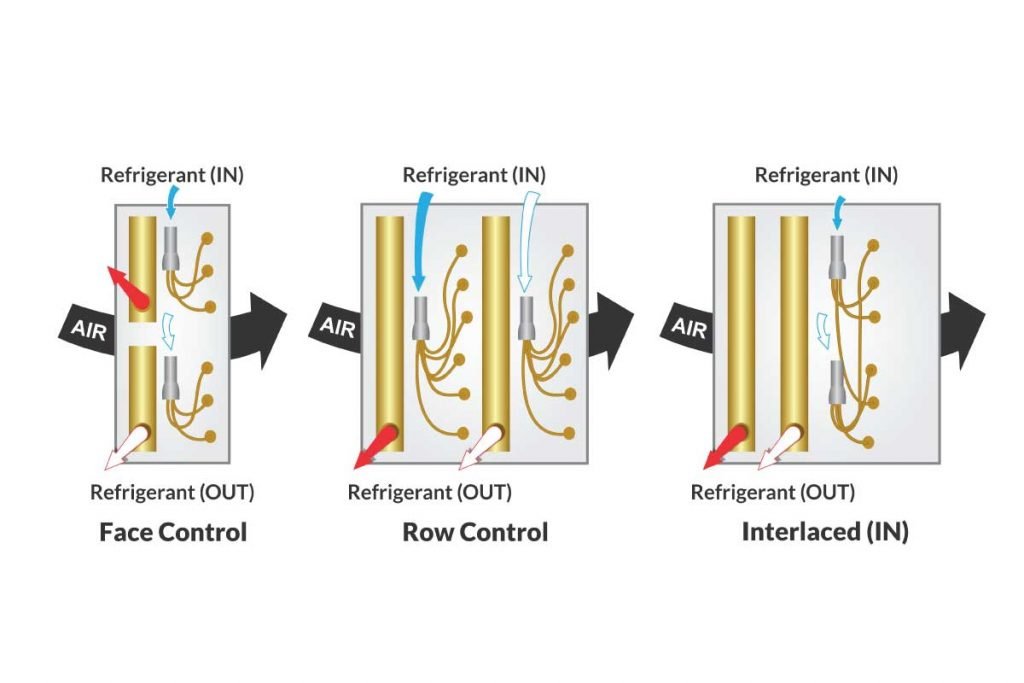

The selection process of the evaporators that operate in a system of refrigeration with CO2 is very similar to the selection of evaporators for ammonia. E Coil Type N Circuiting 14 Fins Per Inch 06 Rows Deep C Fin Design 2400 Fin Height in 14400 Finned Length in 5 E N 14 06 C 2400 x 14400 Tube Outside Diameter 3 0375 4 0500 5 0625 Coil Type E Evaporator Circuiting N Normal F Face Control R Row Control J Interlaced K Interlaced Face Control. Evaporator Coil Circuiting Options.

RowsNL along air flow. In the design of evaporator coils increasing refrigerant mass velocity can enhance the heat transfer of an evaporator coil. Unique interlaced circuiting options assure uniform refrigerant distribution over the entire face area of the coil.

Direct-expansion evaporator coils are used in low temperature refrigeration applications to cool and sometimes dehumidify air. The evaporator curves are plotted as capacity tons versus SST and are based on two fixed factors. EJ Model Type EJ Figure 4 coils come with interlaced circuiting.

Our proprietary circuiting provides for optimal system performance at minimal air-side and refrigerant pressure drops. Design calculate the width from cooling load. Initial evaporator widthLD mm.

The vapor formed is collected at the top of the surge chamber and the remaining liquid refrigerant is returned to the surge chamber. In evaporator coil part of liquid refrigerant boils and converts into vapor. This manner of the cooling coil design could lead to an.

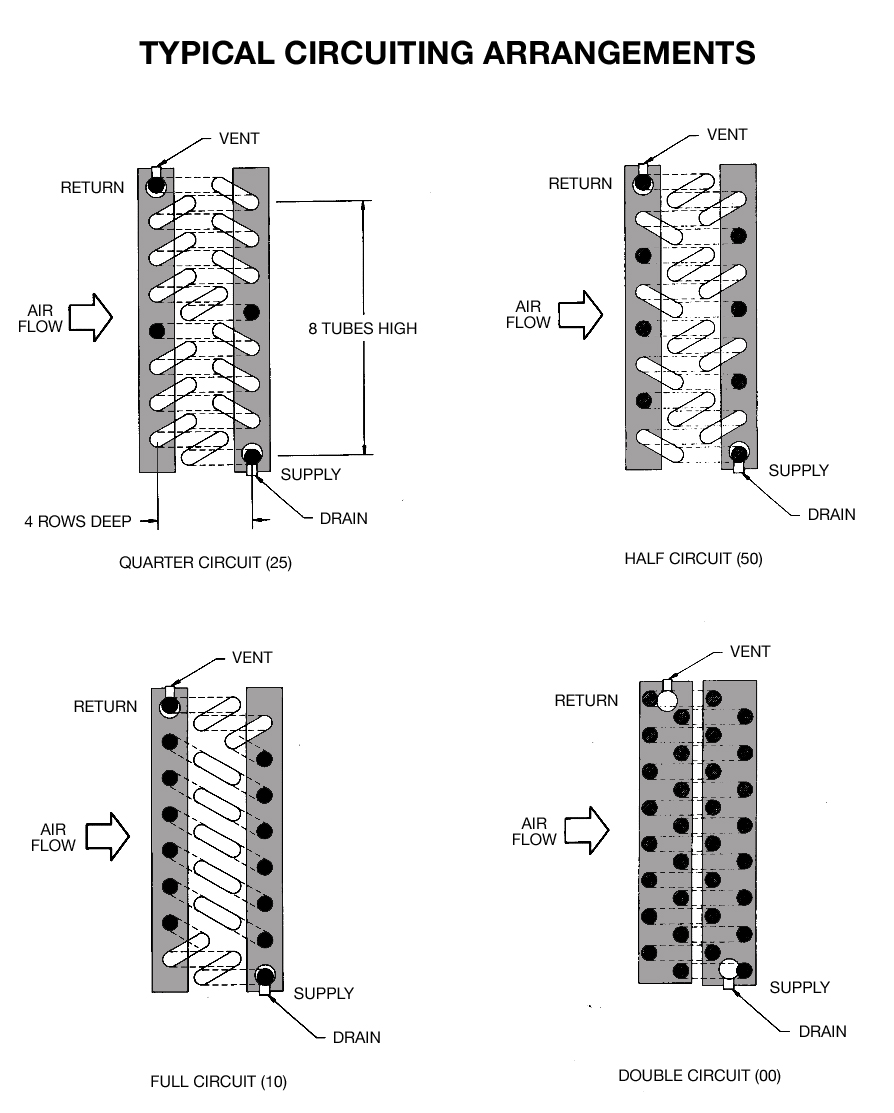

Bruce Nelson President Colmac Coil. Circuits numberNB circuit per row. All evaporator coils are counter flow circuited and equipped with pressure type distributors and all distributor tubes are of equal length to assure equal distribution of refrigerant to each circuit.

Several models for design and simulation of heat exchanging coils are available in the literature with different degrees of sophistication. This makes the fluid want to boil or flash to a gas. Trusted By Tradespeople and Professionals.

Check calculate the cooling load from width. For 12 inch tubes it is 125 inch. The Product Evaporator circuit consists of an insulated pipe an evaporator valves a single wall pipe and sensors.

Pounders Marine Diesel Engines and Gas Turbines Tenth Edition 2021. Circuiting for face control and row control is also available as standard on a wide variety of coils. Developed a general tool for design and simulation of finned-tube heat exchangers that can handle a limited number of pure and mixed refrigerants in evaporation and condensation.

Coil geometry fins rows height length etc. Focuses on Methods to design the cooling and dehumidifying coil or Direct Expansion evaporator coil. Methods to design the cooling and dehumidifying coil either chilled water coil or Dx evaporator coil are usually based on log mean enthalpy or log equivalent dry-bulb temperature difference 1.

The heart of our air heat exchangers is the finned coil built up from a circuit of interconnected tube serpentines and hydrophilic anti-corrosive coated fins to increase the heat exchanging surface. Evaporator Coils DCON. Call Now To Have Your Questions Answered.

Design of Evaporator with CO2 Coolant. Tube and fin material. A new modeling procedure for circuit design and performance prediction of evaporator coils using CO2 as refrigerant By zine aidoun Modelling Fin-and-Tube Gas-Cooler for Transcritical Carbon Dioxide Cycles.

Direct Expansion Evaporator An Evaporator or Direct Expansion DX Coil works on the refrigeration effect cooling occurs when a fluid under. Use your local currency such as kg. Cooling occurs when a fluid under pressure and at a temperature above its normal boiling point has the pressure reduced.

In a coil copper tubes are arranged parallel to one another either in staggered pattern or non-staggered pattern along the length L of the coil. Designed for use in comfort cooling process cooling and refrigeration Coilmaster evaporator coils are proven for use with all of todays refrigerants. Direct expansion type evaporator coils are engineered and designed to deliver the maximum possible heat transfer efficiency under all operating conditions.

Ambient design is 95F then the SST of the condensing unit must be 45F. Evaporator manufacturers commonly require the same data for both refrigerants and likewise performance and selection data will be displayed in the. REFRIGERANT EVAPORATOR DX COIL.

Designed for use in comfort cooling process cooling and refrigeration Madok evaporator coils are proven for use with todays refrigerants. An evaporator or direct expansion DX coil works on the refrigeration effect. Evaporator coils are designed and engineered for efficient operation with all refrigerants.

The performance capabilities are excellent for comfort cooling process refrigeration and moisture control dehumidifying. A variety of load-split options provides the flexibility designers need to optimize the system not only at design conditions but. From the top of the surge chamber refrigerant vapors are drawn in the suction line of the compressor.

Ad Shop Plumbing Heating HVAC Supplies From Premium Brands Including Honeywell Uponor. 1 A staggered pattern is more commonly used. -1 input physical properties at bottom.

This model can handle circuiting but. For use in central systems or duct applications. This form of capacity control.

Our proprietary circuiting provides for optimal system performance at minimal air-side and refrigerant pressure drops. One obvious advantage or reason that you might split a DX coil is that you can shut down 1 of the compressors when the cooling load does not require it.

Chilled Water Cooling Coils Circuiting Made Easy

Chilled Water Cooling Coils Circuiting Made Easy

Numerical And Experimental Studies Of Refrigerant Circuitry Of Evaporator Coils Sciencedirect

Evaporator Coil And Discretization Download Scientific Diagram

The Benefits Of Intertwined Circuiting In Split Coils Fabtech

Understanding Coil Circuiting With A Simple Guide Campbell Sevey

0 comments

Post a Comment